Why Are Manufacturers Doubling Down On Digital Twins?

The industrial metaverse - a connected network of virtual replicas representing physical factories, supply chains and product development processes - has progressed from experimentation to practical application, according to recent research by Siemens and S&P Global.

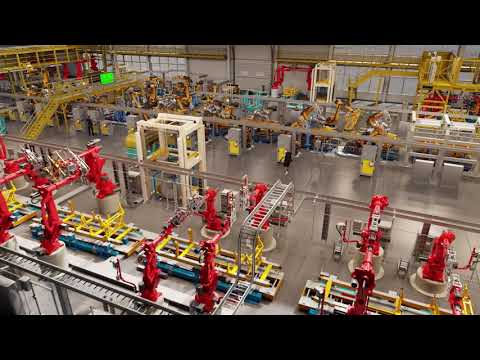

This technology famously leverages digital twins - highly detailed virtual representations of physical assets and operations - along with real-time sensor data and AI to enhance manufacturing efficiency, forecasts maintenance needs and simulate new product designs.

For a full breakdown of what the Industrial Metaverse is, check out this magazine piece before we continue below.

The fundamental technologies that enable the industrial metaverse are being rapidly developed worldwide

Manufacturing sector leads in adoption

The manufacturing sector is at the forefront of adopting the industrial metaverse with 38% of industrial products companies using the technology, which integrates digital twins, AI and IoT sensors to simulate and optimise production processes.

The food and beverage industry, along with the electronics sector, shows a 26% adoption rate, according to the study that included firms from Australia, Canada, China, Germany, India, the UK and the US.

“The fundamental technologies that enable the industrial metaverse are being rapidly developed worldwide,” says Peter Koerte, Chief Technology Officer and Chief Strategy Officer at Siemens AG.

“Many companies are not only experimenting with these technologies but are already employing and scaling concrete use cases that demonstrate the added value of the industrial metaverse.”

Changes in spending patterns

The research highlights a change in spending behaviour, with 30% of companies like manufacturers now investing more than US$10m annually in industrial metaverse technologies – double the share from the previous year.

Medium-sized businesses are showing notable progress, with 68% reporting year-over-year increases in investment.

However, companies with fewer than 1,000 employees continue to face resource challenges, even though 58% have boosted their technology spending.

- 30% now invest over US$10m annually, double from previous year

- 62% increased spending in 2024

- 81% of businesses using, testing or planning metaverse solutions

“The industrial metaverse is proving to be more than just a promising concept – it’s emerging as a core driver of the digital transformation," says Brian Partridge, Head of Research at S&P Global Market Intelligence 451 Research.

"Companies of all sizes are committing substantial resources and advancing from testing to implementing integrated solutions that can master complex challenges on a large scale.”

North American manufacturers are leading in technology adoption, with 23% identified as leaders in the field, followed by Europe at 19% and Asia-Pacific at 15%.

In the US, 38.4% of companies report active usage, with an additional 35.1% currently in testing phases. China ranks closely behind, with 37.9% implementation and 39.9% in testing. Germany shows 34% active usage and 31.9% testing rates.

Other regions, including Canada, Australia, the UK and India, display implementation rates between 21% and 27%, while their testing rates range from 29% to 36%.

The increase in industrial metaverse investment has been driven by significant technology partnerships.

In 2022, Siemens announced an expansion of its collaboration with Nvidia, the graphics and AI computing leader, to integrate their industrial platforms.

The partnership links Siemens Xcelerator, an open digital business platform, with Nvidia’s Omniverse, a 3D design and collaboration system. This integration allows manufacturers to build physics-based digital models driven by real-time AI and simulate and test production processes prior to physical deployment.

"Photorealistic, physics-based digital twins embedded in the industrial metaverse offer enormous potential to transform our economies and industries by providing a virtual world where people can interact and collaborate to solve real-world problems.” says Roland Busch, President and Chief Executive Officer of Siemens AG.

Make sure you check out the latest edition of Manufacturing Digital and also sign up to our global conference series - Manufacturing LIVE

Manufacturing Digital is a BizClik brand.