Joint venture featuring Stratasys, Lockheed Martin, and Padt to deliver 3D printed parts for NASA

The applied additive technology solutions firm, Stratasys, Phoenix Analysis & Design Technologies (PADT), and Lockheed Martin Space have joined a joint venture to provide NASA with 3D printed parts.

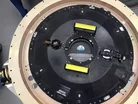

The additively manufactured parts will be used for NASA’s Orion deep-space spacecraft.

The parts will be created using Stratasys’ advanced materials including an ESD variant of the new Antero™ 800NA, a PEKK-based thermoplastic offering high performance mechanical, chemical, and thermal properties.

The 3D-printed parts will be produced in Lockheed Martin’s lab in conjunction with PADT.

“Working with PADT, Stratasys, and NASA has enabled us to achieve highly consistent builds that move beyond the realm of prototyping and into production,” commented Brian Kaplun, Manager of Additive Manufacturing at Lockheed Martin Space.

SEE ALSO:

“We’re not just creating parts, we’re reshaping our production strategy to make spacecraft more affordable and faster to produce.”

NASA’s Orion projects aims to reach to the moon and thousands of mils beyond, using the world’s most powerful rocket – the Space Launch System.

The space company will be running two missions – EM-1 and EM-2 – which will travel with and without passengers, and will use 100 3D printed production parts.

“The demands of space travel require extremely high performance materials and the most rigorous manufacturing processes in the industry,” remarked Scott Sevcik, Vice President of Manufacturing at Stratasys.

“Part integrity and repeatability are essential and must pass NASA’s demanding testing and validation process.”

“Based on decades of experience delivering strong and lightweight additive manufacturing solutions for leaders across the aerospace industry, Stratasys technology is ideally suited to match the high-reliability manufacturing processes required for production parts in space exploration.”