GKN Aerospace to significantly reduce production time by embracing Stratasys additive manufacturing

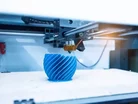

The US-based 3D printing manufacturer, Stratasys, has confirmed that GKN Aerospace is upgrading its production times and removing design constraints for multiple tooling applications since utilising additive manufacturing at its UK headquarters.

The aerospace manufacturer, GKN, is set to invest in Stratasys’s F900 Production 3D printer with the aim of reducing lead times for production-line tools, in addition to creating complex parts which can’t be made through the use of traditional manufacturing methods.

Tim Hope, Additive Manufacturing Centre Manager, at GKN Aerospace, said: “Since integrating the F900, we have dramatically reduced production-line downtime for certain teams and are enjoying a new-found freedom to design complex tools.”

It is anticipated that GKN serves more than 90% of the aircraft and engine manufacturers in the world and provides the companies with engine systems, aerostructures and technologies.

See more

- Bosch confirms strategic technology partnership with SiTime to accelerate MEMS timing

- Mercedes announces first fully electric car to compete with Tesla

- Hitachi unveils new solution to help social infrastructure field in joint venture with VMware

- Read the latest issue of Manufacturing Global here!

With lead-times significantly reduced by utilising in-house 3D printing to take on the same role as a metal or plastic replacement tool, it will enable jobs to be completed within hours.

“We can now cost-effectively produce tools for our operators within three hours,” Mr Hope continued.

“This saves critical production time, and by printing in engineering-grade thermoplastics, we can produce 3D printed tools with repeatable, predictable quality every time. All while matching the quality of a traditionally-produced tool, and reducing the costs and concessions compared to equivalent metallic tooling.”

It has also been revealed that GKN has also confirmed a reduction of 40% in its material waste as a result of the decision.