The University Manufacturing Circuit Boards from Leaves

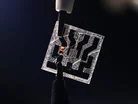

The Dresden University of Technology, a renowned German research institution, has created prototype biodegradable circuit boards made from magnolia leaves, representing a significant step forward in the sustainable manufacturing of electronic components.

This innovative technology, known as 'leaftronics,' stems from research led by Postdoctoral Scientist Rakesh Nair at TU Dresden's electronics laboratory.

The process involves utilising magnolia leaf structures coated with ethyl cellulose, a biodegradable polymer, to produce circuit boards compatible with standard manufacturing techniques.

"Substrates made of biodegradable polymers could not be used for electronic device or circuit fabrication until now because they naturally do not handle elevated temperatures well," Rakesh explains.

Challenging traditional manufacturing methods

The process begins by stripping magnolia leaves to their vein structure, which is subsequently coated with ethyl cellulose. The resulting material can withstand temperatures of up to 180C, meeting the requirements of circuit board production while preserving its biodegradability.

These organic circuit boards are compatible with laser cutting and standard component soldering techniques. They can also be processed in acid baths to recover metals before fully degrading through composting within 30 days.

Energy efficiency was a key focus during development, offering a stark contrast to traditional circuit board manufacturing, which demands high energy consumption during production.

John W. Mitchell, President and CEO of IPC, an electronics manufacturing association, and Board Member for the US Partnership for Assured Electronics, says: "With the world producing over 50 million tons of e-waste every year, innovations like these could help reduce the environmental impact of modern electronics."

Printed circuit boards (PCBs), essential components that connect electronic elements in devices, significantly contribute to electronic waste due to their non-recyclable fibreglass and composite plastic construction.

Disposal methods currently involve landfill deposition or incineration to recover metals.

While previous research has explored biodegradable electronics using materials such as paper, silk, and fungi, TU Dresden's leaf-based approach offers thermal and mechanical properties more suited to electronics manufacturing.

The natural leaf scaffold structure simplifies production processes while retaining the necessary performance characteristics.

Addressing adoption challenges

This technology tackles a key challenge in the electronics industry, where PCBs are designed for long lifespans, yet are integrated into products with shorter life cycles.

"Circuit boards today are built for permanence, yet they're used in products with a short lifecycle," adds Rakesh. "The challenge isn't just in developing the materials, but in reshaping an entire sector to embrace a more sustainable future."

The development of leaftronics also aligns with the growing focus in the electronics industry on sustainable component manufacturing.

Current PCB manufacturing standards prioritise durability, with materials designed to retain structural integrity for decades.

TU Dresden's research team has conducted durability testing on the organic circuits, although long-term performance data is still being evaluated.

The technology requires further assessment against existing PCB reliability standards before it can be considered for potential industry adoption.

This development comes at a time when electronics manufacturers are increasingly focusing on sustainable production methods. Recent industry initiatives have highlighted recycling and refurbishment programmes, but biodegradable components offer a new approach to waste reduction.

Projections suggest that global electronic waste volumes could reach 100 million tonnes by 2050 without technological intervention.

TU Dresden's organic circuit development presents a potential alternative for manufacturing as electronics manufacturers explore more sustainable production methods.

The research forms part of TU Dresden's broader programme investigating the applications of organic electronics. The university is equipped with dedicated laboratory facilities for advancing sustainable electronics development.

Explore the latest edition of Manufacturing Digital and be part of the conversation at our global conference series, Manufacturing LIVE.

Discover all our upcoming events and secure your tickets today.

Manufacturing Digital is a BizClik brand.

- Schneider Electric's Commitment to Sustainable ManufacturingSustainability & ESG

- Lenovo & Saudi Alat Building Green Manufacturing FacilitySustainability & ESG

- Nissan Brings Biodiversity to the Factory through RewildingSustainability & ESG

- Manufacturing & Mobility LIVE: Neby Ejigu, FINN PartnersTechnology