PTC White Paper: Digital Transformation in Manufacturing

Using a proven methodology for defining and achieving Operational Excellence will allow manufacturers to position themselves to achieve goals faster, at a lower cost and with better results than relying on a less structured approach, a white paper from LNS Research has found.

Entitled ‘The Road to Digital Transformation Success: A Methodology to Modernise Operational Excellence,’ the white paper states that the largest hurdle manufacturing businesses face today is a lack of communication and collaboration.

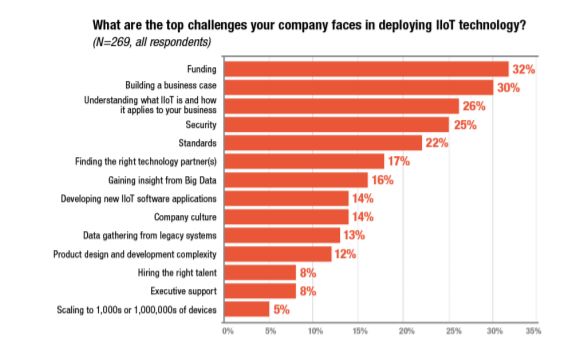

“Even when there is a desire to implement something as powerful as Industrial Internet of Things (IIoT) technology, obstacles like funding, building a business case, and understanding how it will help all boil down to those two fundamental factors,” the white paper says.

It adds that although some organisations have made progress in adapting and managing the challenges of the convergence of information and operational technology, and despite having a plan of where to go (i.e.: Operational Architecture), there is still very little actual progress towards transformation.

“The hurdle that most often holds companies back is that they haven’t navigated the bridge between strategic vision setting and Operational Architecture: defining Operational Excellence. Companies that truly embrace Digital Transformation as a way to institute new business models or achieve greater competitive advantage do what’s necessary to “get out of their own way” – eliminating the challenges that stand between them and their target,” the white paper says.

Therefore, LNS Research recommends four key steps and activities that companies can carry out, to achieve Operational Excellence, and thus pave the way forward for Digital Transformation.

Despite differences in manufacturing style, industry, geography, and business size, by applying these basic elements with rigor, companies in the manufacturing and asset-intensive industries will be able to achieve results, it states.

Organisations that want to achieve Operational Excellence to smoothen the way towards Digital Transformation can follow these steps:

1. Understand what Operational Excellence really means in context of Digital Transformation. Using a definition that is too broad, too narrow, or even slightly off-base will not help the business toward Digital Transformation. In fact, the wrong definition could lead to a “bad” roadmap and sabotage the effort.

2. Create a strategy for Operations Excellence. Using a proven strategy can help the organization accelerate and validate first steps and will keep efforts on-track into the future. While the business may evolve, and the stakeholders may move on, a solid strategy will survive and support even the most turbulent changes within and outside the organization.

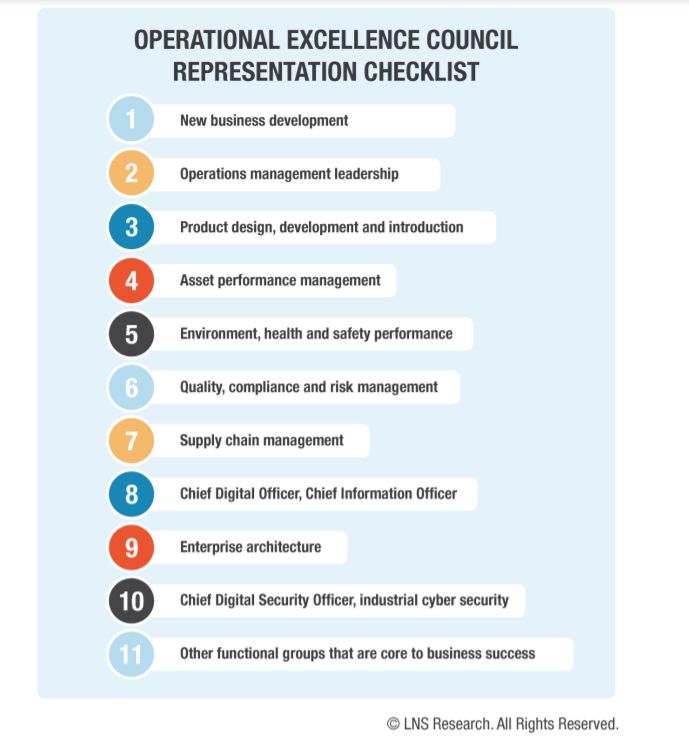

3. Form an Operational Excellence council; ensure the right representation. It is not enough to gather the people who are most eager for Digital Transformation, or who may feel the most immediate impact from it. It is critical to gather a thorough cross-section across functions and levels throughout the company to ensure the council considers every aspect that may affect or experience the effects of Digital Transformation.

4. Look to the right people for help. Certainly, vendors and consultants have a tremendous amount of experience and a wealth of insight to offer, as do their clients. However, exercise caution against getting pigeonholed into systems or platforms that might not be quite right for the business. Look to impartial third parties like research and analyst firms, or consulting companies that do not specialize in anyone “flavour” of solution.

Credits: LNS Research.

- Manufacturing & Mobility LIVE: Become a Media PartnerProduction & Operations

- Want to Sponsor Manufacturing & Mobility LIVE in 2024?Production & Operations

- SAVE THE DATE: Manufacturing & Mobility LIVEProduction & Operations

- Private 5G: How is NTT DATA Future-Proofing Manufacturing?Smart Manufacturing