Mondelēz & Amcor to reduce food packaging plastic waste

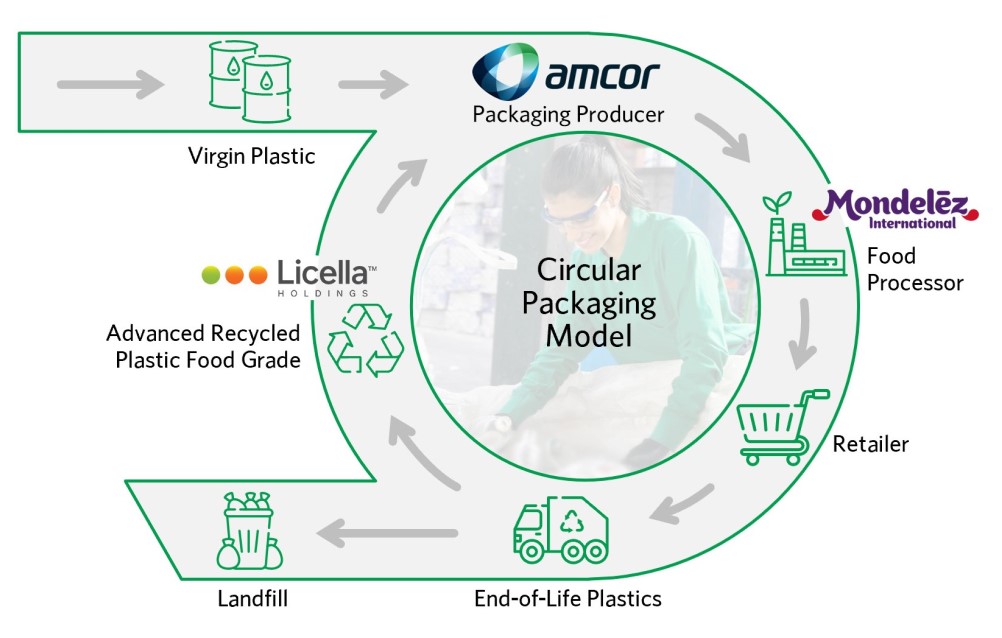

Food manufacturer Mondelēz International has partnered with packaging manufacturer Amcor, to build a snack-based circular economy using Cat-HTR, an advanced hydrothermal liquefaction (HTL) technology.

Sustainable food packaging manufacturing

Mondelēz International is known for its snacks, from Ritz crackers to its range of biscuits. Belvita is the most popular breakfast biscuit in the world, while Oreo is the number one cookie. First sold 1912, the Oreo has become the world’s top selling sandwich biscuit. It takes biscuits manufacturers two hours to bake one Oreo and the total amount of Oreos baked in one year could circle the earth five times.

Amcor was founded in 1864 and is based in Zurich, Switzerland. The company aims to make packaging light-weighted, recyclable and reusable.

The two manufacturers have partnered to use Cat-HTR in the packaging of snacks and reduce the volume of plastic waste.

Cat-HTR is an advanced hydrothermal liquefaction (HTL) technology, which uses hot, pressurised water to continuously recycle end-of-life plastic that would otherwise be sent to landfill.

Advanced Recycling Victoria (ARV) is a new Australian facility, which will process 20,000 tonnes of end-of-life plastic each year. This will later be increased to 120,000 tonnes per year.

Through Amcor, Mondelēz International expects to have access to recycled content from this site to meet much of its Australian soft plastic packaging needs.

Manufacturing plastic packaging from recycled sources

The investments will help Licella construct one of the first advanced recycling facilities in Australia. Licella will use its Cat-HTR™ technology to recycle end-of-life plastic back into a crude oil substitute suitable to manufacture new food-grade plastic packaging.

“While plastic plays an important part in the security, quality, protection and preservation of food products, there is a gap in sustainable local recycling solutions,” says Christine Montenegro McGrath, Senior Vice President and Chief Global Impact and Sustainability Officer at Mondelēz International. “Our packaging strategy is focused on using better packaging and helping to build better systems. This investment brings together multiple stakeholders in the supply chain to scale the infrastructure and technology needed to help create a more sustainable future for plastics and is part of our longer-term focus on working toward our goal of net-zero packaging waste by supporting circular economies.”

“This is the leading technology of its kind globally, and it was developed here in Australia. This investment will help advance our Australian facility at a time when demand for sustainable plastic solutions, that also help provide food-grade recycled content, is growing exponentially,” said Dr Len Humphreys, CEO of Licella.

“Amcor is continually seeking opportunities to invest in new technologies that will bring long-term benefits to our customers, consumers and the planet,” agreed Frank Lehmann, Vice President of Corporate Venturing and Open Innovation at Amcor. “We recognise our products can play a vital role in the circular economy, and partnerships like this enhance our ability to deliver innovative solutions for our customers, like Mondelēz International,” said Lehmann.

“Amcor will be able to meet increasing customer demand for recycled content in the region with this investment, as well as take another step closer to achieving our target of 30% recycled content across Amcor’s portfolio by 2030,” said Mike Cash, President of Amcor Flexibles Asia Pacific.

*************************************************

For more insights into Manufacturing - check out the latest edition of Manufacturing Magazine and be sure to follow us on LinkedIn & Twitter.

Other magazines that may be of interest - Healthcare Digital.

*********************************************

BizClik is a global provider of B2B digital media platforms that cover 'Executive Communities' for CEO's, CFO's, CMO's, Sustainability Leaders, Procurement & Supply Chain Leaders, Technology & AI Leaders, Cyber Leaders, FinTech & InsurTech Leaders as well as covering industries such as Manufacturing, Mining, Energy, EV, Construction, Healthcare + Food & Drink.

BizClik, based in London, Dubai & New York offers services such as Content Creation, Advertising & Sponsorship Solutions, Webinars & Events.

- Henkel: Optimising Washing Through Autonomous SensorsSustainability & ESG

- BMW: Creating Economic Circularity through Battery CreationSustainability & ESG

- Aggreko: UK Energy Manufacturers must Shore Up Supply ChainSustainability & ESG

- Capgemini: Gen AI Cause of Spiking Semiconductor DemandAI & Automation