Top 10: Manufacturing trends 2014

10. eSourcing

Supply chain management and procurement efficiencies have become as much of a cost-saving feature in the manufacturing process as any, bringing eSourcing to the fore.

Incorporating sub-themes such as B2B agility and the industrial internet, manufacturers are growing towards eSourcing, both in terms of purchasing and sales.

9. ERP

While it certainly isn’t a new concept for 2013, the role of Enterprise Resource Planning (ERP) in the manufacturing industry is continuously taking on new dimensions.

Back in September, Pat Garrehy of Rootstock used the analogy of different flavoured ice creams to highlight more than 30 options now open to manufacturers in the ERP market place.

8. M2M

In July of this year, Vodafone shared findings from its M2M Adoption barometer, predicting that half of all companies will be utilising the trend by 2015.

Key factors behind the rise in uptake have been attributed to the falling price of M2M hardware and the subsequent accessibility for SMEs to whom the technology could be most beneficial.

7. Supply Chain Risk Management

Again, through the advent of the industrial internet, cloud optimisation and M2M technologies, risk management has become a much more efficient cog in the supply chain management machine.

As Infosys highlighted in its top trends infographic earlier in the year, “intelligent technology will empower manufacturers to react faster to disruptive events by monitoring risks and identifying alternate suppliers”.

6. Social Media

Similarly to ERP, social media is hardly a new concept, but in the same way that the race to find a presence onFacebook or Twitter was pivotal a few years back, the new challenge is to be found among the melee.

The congestion has now made the need for an effective social media strategy a key differentiator.

5. Reshoring

As globalisation continues to take hold and manufacturers face tough decisions in the light of faulting economies and strategic expansion, reshoring has become an ever-more prevalent occurrence.

Bringing into play issues of employment, training and skill retention, the location of a business has never been so vital given the global supply chain readily available to businesses.

4. Plug-and-Play plants

Bridging both the cloud and the Internet of Things while seemingly overriding the sometimes lengthy ERP introduction, the advent of plug-and-play plants could be instrumental in the future of manufacturing.

The trend enables a wireless connection between factory and headquarters, making automation, cost cuts and expansion to emerging economies positives to take from its adoption.

3. Internet of Things

Of course, the cloud, as an individual trend, could have topped this countdown given its influence on many of the inclusions; the Internet of Things certainly being one of them.

The ability to connect and communicate between various mechanical items is an intriguing prospect for both consumers and manufacturers alike, and one that the likes of Intel are already preparing for.

2. Big Data

Where the race for efficiencies and performance is paramount, every ounce of data is invaluable to a manufacturer.

Being able to analyse everything and leave nothing to chance is now a possibility with big data, and despite playing a big role across all business sectors, manufacturers such as Ford are benefitting from the trend more than most.

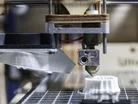

1. 3D Printing

While 3D printing has been on the manufacturing radar for a number of years now, the saturation of the trend in mainstream media and in the general public’s consciousness has escalated dramatically in 2013 with people now pondering the consequences of additive manufacturing becoming a consumer process as well as an industry function.

This revolution is bound to continue into 2014, especially as leading manufacturers begin to highlight the results of their 3D printing efforts.

Lockheed Martin and HP are just two of the world’s leading industry names to have openly voiced their fascination over the trend, with the latter confirming that it would be manufacturing 3D printers in the not too distant future.

Lockheed Martin will be just one of the thousands of manufacturers utilising the machines in their production line, as sectors including auto-manufacturing, aviation, process machining, construction and hi-tech technology looks to cash in on the future of manufacturing.